As the dust continues to settle on a severe supply chain disruption caused by Covid-19, companies are embracing the use of data to forecast trends and customer actions that lead to proactive decision-making.

In a recent study, supply chain professionals ranked what they believe is needed to overcome their biggest challenges, including:

- Using automation to get products to consumers faster

- Using inventory and network optimization to remove stocking gaps

- Using data and technology to provide transparency up and down the supply chain

In an instant gratification world where next-day delivery is king, supply chain professionals are searching for comprehensive telematics to monitor assets, labor and productivity. Tools like iWAREHOUSE® from The Raymond Corporation give manufacturing facilities, warehouses and distribution centers the ability to measure the individual performances of people and units and gather insights for data-driven decisions.

iWAREHOUSE provides timely operator and equipment data that can be used to optimize operations and improve safety. With comprehensive telematics, you’re able to:

- Monitor equipment usage in a timely manner

- Track operator access and utilization

- Improve safety through impact reporting and checklists

- Turn data into results that reduce costs

Equipment monitoring for rightsizing and operational efficiency

Finding ways for companies to continue usage of existing equipment while awaiting new units or the installation of automated technology is a primary responsibility of today’s forklift fleet management specialists.

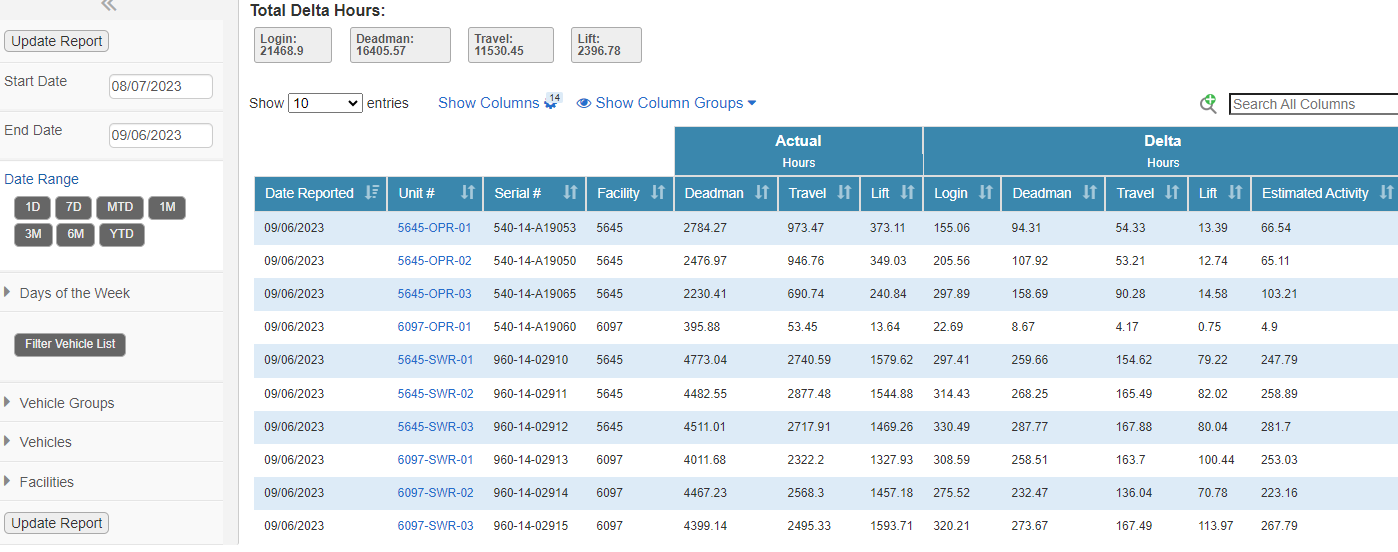

Usage reports from iWAREHOUSE, for example, can be used to make recommendations on how to rotate equipment to balance unit usage hours and reduce cost per hour. Data collected on individual trucks can be used to rightsize a fleet or to optimize vehicle utilization to prevent premature aging.

Track operator access and utilization

Visibility into the individual performance of trucks and operators can not only help companies rightsize fleets, but also get employees in the right seats. By tracking operator login, travel, lift, deadman and utilization rates, iWAREHOUSE gives warehouse managers the ability to make data-driven decisions that improve operator efficiency and increase productivity.

For example, the iWAREHOUSE Gateway allows users to filter data by truck type or facility to measure the efficiency of certain types of operations or pinpoint problem areas within the warehouse.

Improve safety through impact reporting

Gaining insight into impacts is another benefit of using iWAREHOUSE. Analyzing impact data can help identify operators who need additional training or even a layout change within the warehouse that could reduce impacts. Repeated impact warnings in a singular area, for example, may suggest that wire guidance is needed to automatically guide vehicles down narrow aisles.

Turn data into results that reduce costs

Advanced, predictive analytics is key for companies struggling to improve throughput and efficiency in the face of continuing labor shortages and increasing consumer demand.

iWAREHOUSE is a complete telematics solution that is compatible with hundreds of makes and models of industrial vehicles. Through a single gateway that is accessible from any web-based device, the subscription-based service puts real-time fleet data at your fingertips.

Data can be customized to appear in varying forms from lists to graphs to heat maps, with reports sent via email or text on a preferred cadence. Reports can be tailored to correspond with key performance indicators (KPIs) to help companies get the most from their data.

Go HERE to download our whitepaper, iWAREHOUSE®: Using Data to Optimize Operations, Improve Safety and Prevent Supply Chain Disruptions.